· Roger Almirall Jou · Project · 9 min read

Barcelona International Young Student Challenge 2025

During 7 days, students from several countries arround the world have developed a PocketQube, going from concept and design, to implementation and validation.

BIYSC 2025: Students Complete Full Satellite Development Cycle in Groundbreaking Week-Long Program

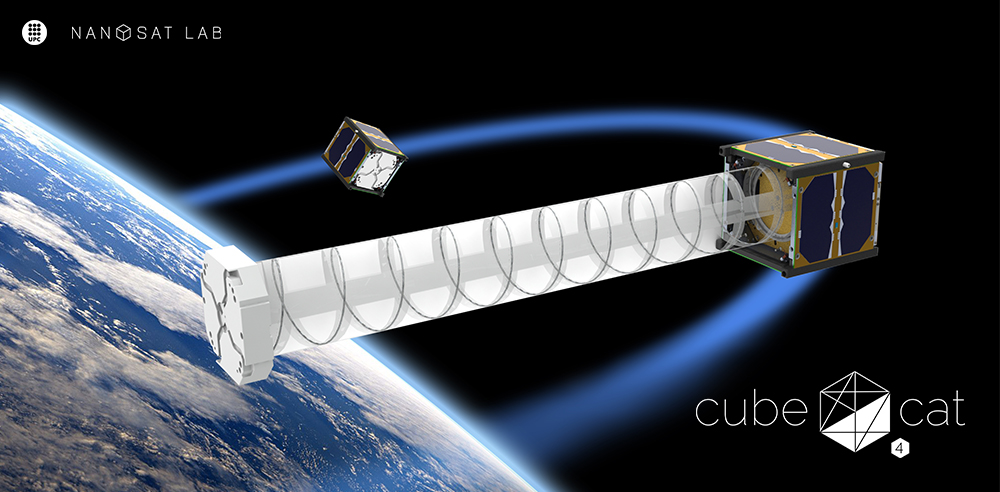

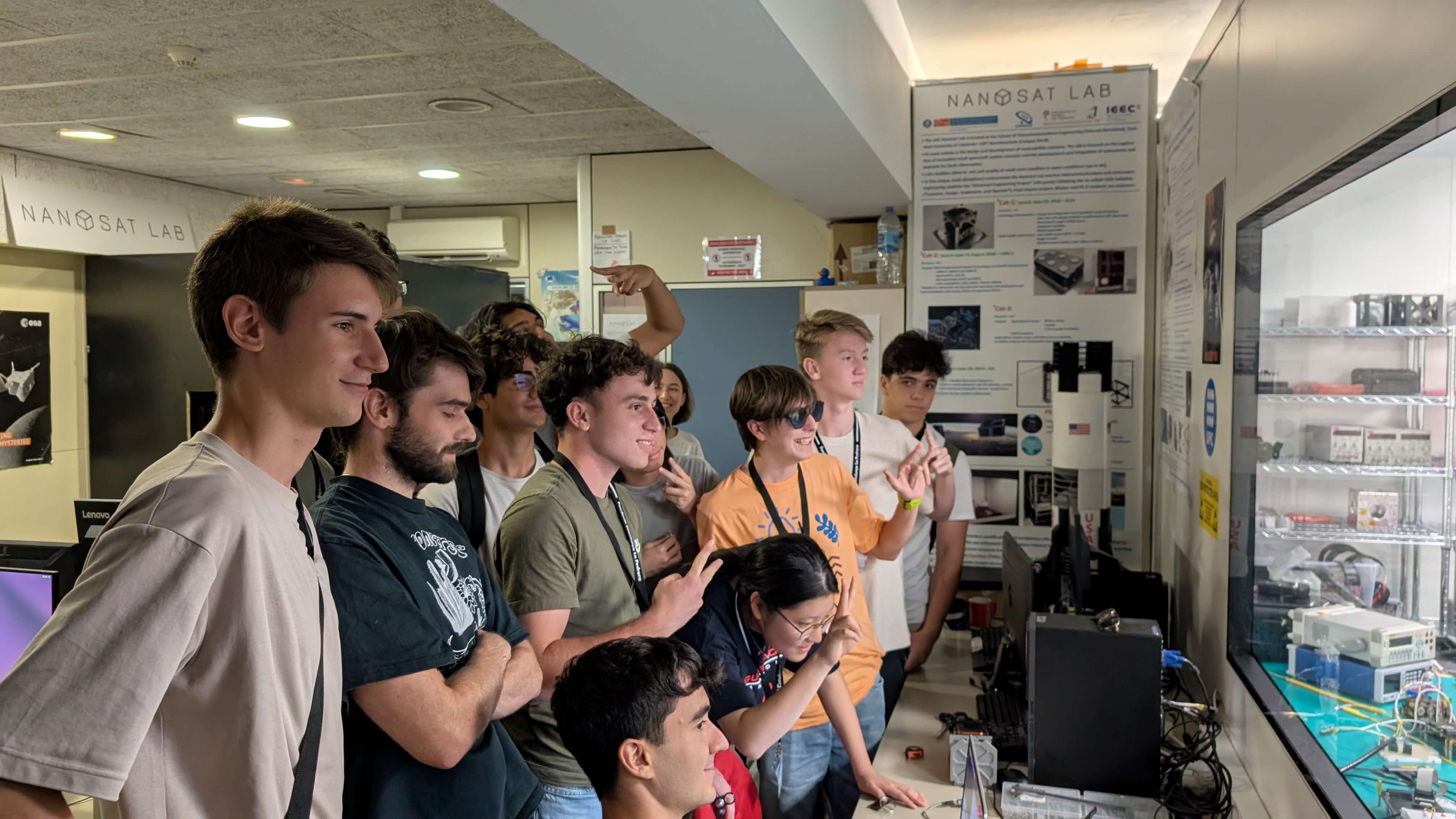

Barcelona, July 2025 - The UPC-NanoSat Lab has successfully concluded the 2025 edition of the Barcelona International Youth Science Challenge (BIYSC), where ambitious students from around the world completed an extraordinary journey from satellite concept to operational mission in just seven intensive days. This year’s program saw participants design, manufacture, test, and operate their own PocketQube satellite, gaining hands-on experience with the complete spacecraft development lifecycle.

This program has been concieved and organized by Fundació la Pedrera in the 2025 BIYSC Programme. This work conducted in the UPC NanoSat Lab has been done in collaboration with the ARANEM Radio Club.

From Concept to Reality: A Complete Space Mission Experience

The 2025 BIYSC program represented a unique educational opportunity where theoretical knowledge met practical implementation. Under the guidance of UPC-NanoSat Lab experts, students didn’t just learn about space technology—they built it, tested it, and operated it using the same methodologies employed by professional space agencies and commercial satellite companies.

“What makes this program truly special is that students experience every aspect of a real space mission,” explains a program coordinator from UPC-NanoSat Lab. “From the initial requirements definition to the final data transmission, they work with actual space-grade processes and technologies.”

Mission Design and Requirements Engineering

The program began with students diving into the fundamental challenge that faces every space mission: defining clear, achievable requirements. Working with mission design principles used by major space agencies, participants learned to balance technical constraints with mission objectives, considering factors such as orbital mechanics, power budgets, and communication links.

Students utilized professional tools including MATLAB for orbital simulations and budget calculations, experiencing firsthand how mission parameters like data transmission rates, power consumption, and orbital characteristics are interconnected. This systems engineering approach demonstrated the complexity of space missions and the importance of thorough planning before any hardware development begins.

A critical component of this phase involved addressing ethical considerations in space technology. Students explored contemporary challenges including space debris mitigation, radio frequency interference, and the implications of mega-constellations on low Earth orbit accessibility. This ethical foundation ensured that technical decisions were made with broader responsibility in mind.

Hardware Development and Manufacturing

Payload Design and Implementation

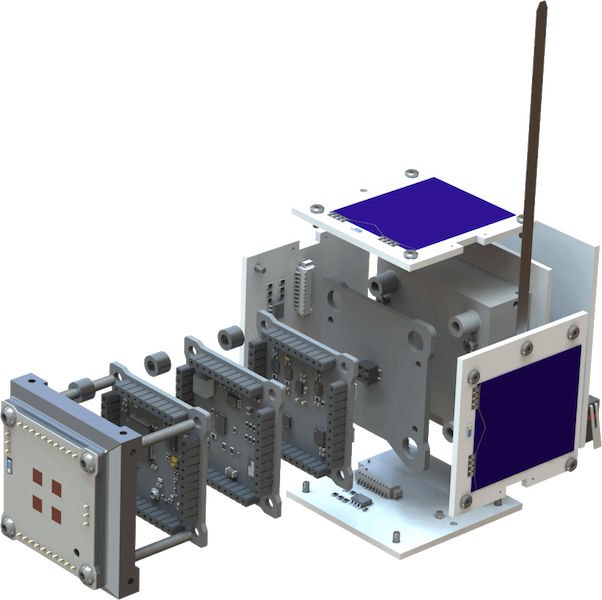

The heart of each student’s satellite was a custom-designed camera payload system. Using industry-standard KiCad software for electronic design and SolidWorks for mechanical components, students created complete payload solutions that included both the electronic systems and structural integration components.

The payload development process mirrors that used in professional satellite development, with students progressing through Engineering Model (EM), Qualification Model (QM), and Flight Model (FM) phases. Each PocketQube featured a VGA camera system capable of capturing optical spectrum images, complete with custom control electronics designed and manufactured by the students themselves.

PCB Manufacturing and Assembly

In a rare educational opportunity, students manufactured their own printed circuit boards using chemical etching processes. Working in controlled laboratory conditions with ferric chloride solutions and following space-grade assembly procedures, participants gained invaluable experience with the manufacturing constraints that influence satellite design.

The soldering and assembly phase followed space industry quality standards, with students learning the precision techniques required for reliable operation in the harsh space environment. Each component placement and solder joint was executed with the care demanded by mission-critical hardware.

Software Development and Integration

The software development phase encompassed multiple layers of complexity. Students programmed STM32 microcontrollers using embedded C, implementing camera control systems, communication protocols, and system management functions. The software architecture required careful consideration of resource constraints and reliability requirements typical of space applications.

A particularly challenging aspect involved integrating individual subsystem code into the spacecraft’s main software framework. Students learned to work within existing code architectures while ensuring their payload functionality operated seamlessly with other spacecraft systems, including power management, attitude control, and communication systems.

Communication Systems and Ground Operations

LoRa Communication Implementation

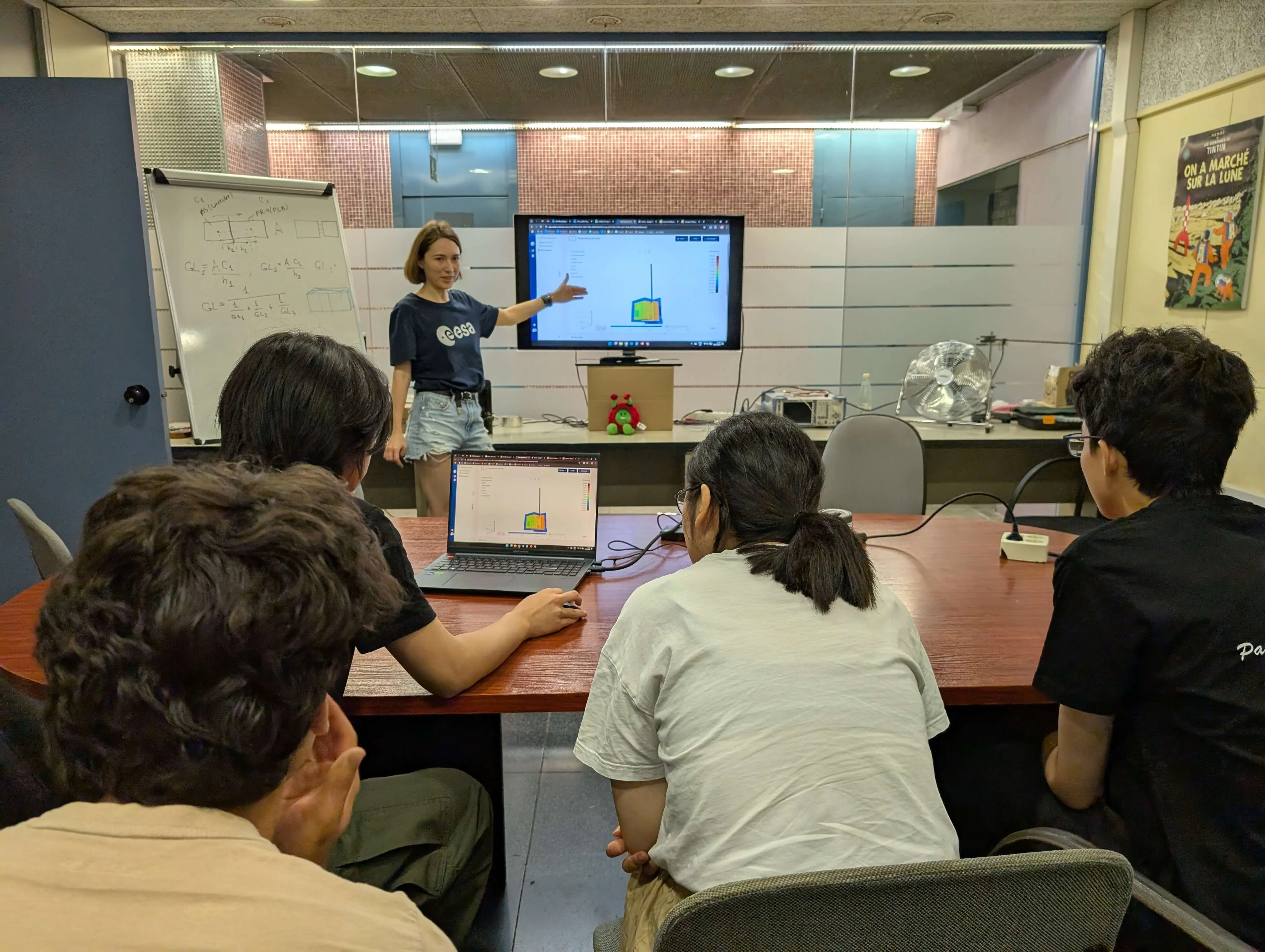

Students designed and implemented complete communication systems using LoRa technology, enabling their satellites to transmit image data and receive commands from ground stations. This involved not only the technical implementation of radio frequency systems but also the development of communication protocols and packet structures suitable for space-to-ground links.

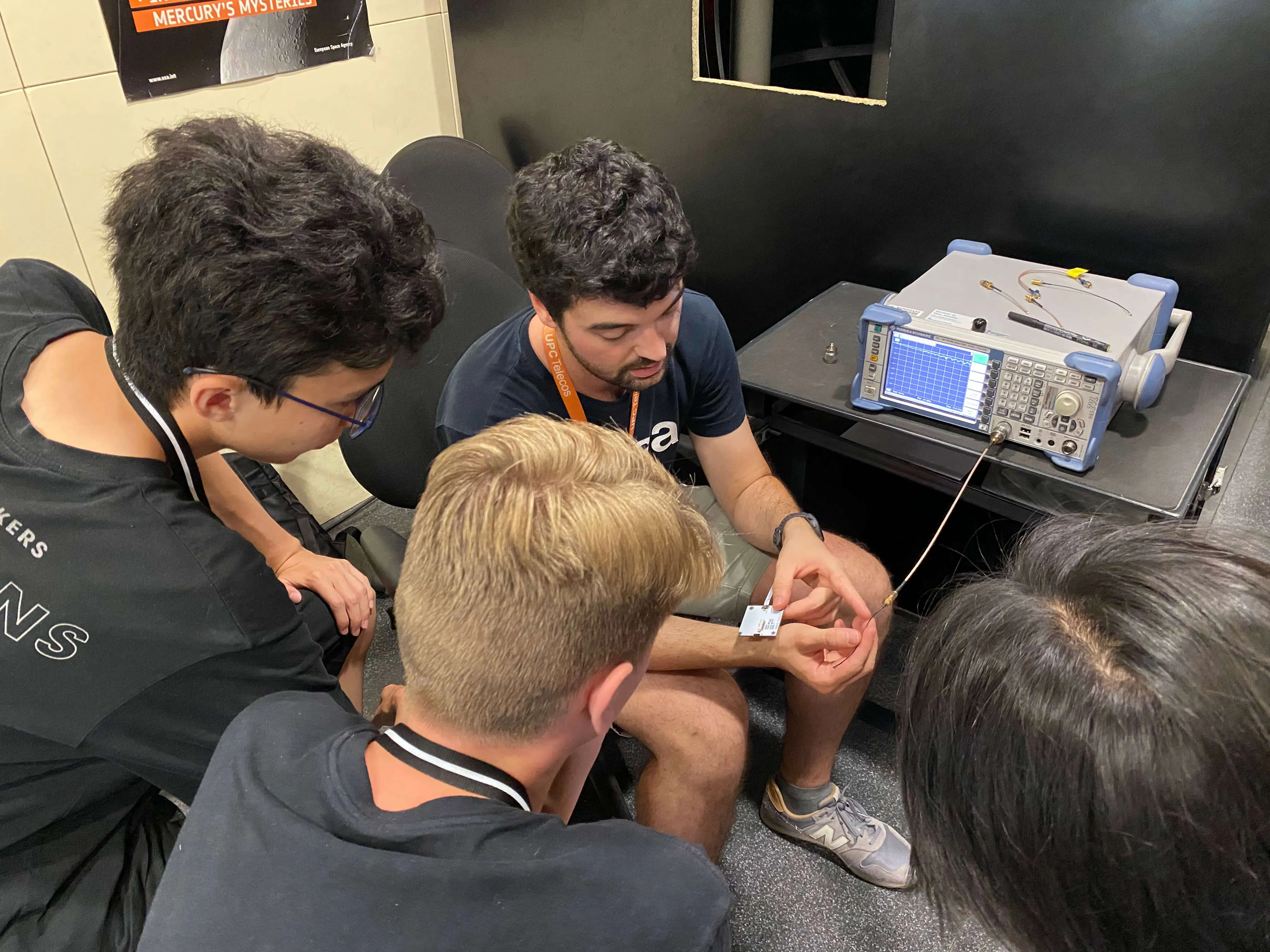

The communication development included practical work with spectrum analyzers and other RF test equipment, giving students experience with the measurement and validation techniques used in professional satellite development. Students learned to balance data transmission rates with power consumption and link reliability constraints.

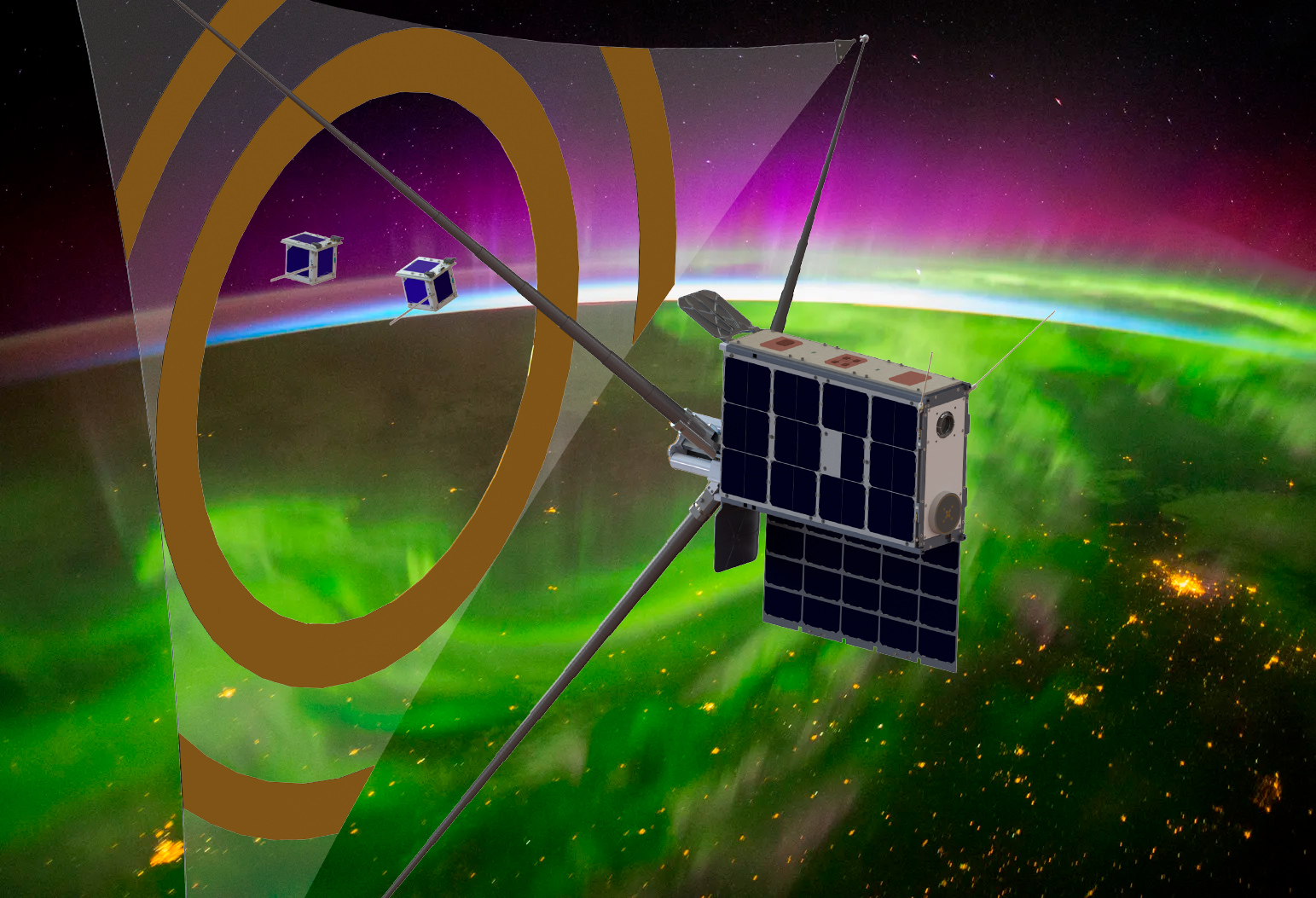

Antenna Design and Deployment

Each team designed and manufactured custom monopole antennas resonating at 868 MHz, using vector network analyzers to characterize antenna performance. The challenge extended beyond basic antenna design to include deployment mechanisms, as the antennas needed to be stowed during launch and deployed once in orbit.

Students developed innovative deployment solutions using Dyneema wire and controlled burn resistors, creating mechanisms that could reliably deploy antennas in the space environment. This exercise demonstrated the complexity of deployable structures and the engineering challenges involved in space mechanisms.

Ground Station Development

Complementing their satellites, students assembled complete ground station systems capable of commanding their spacecraft and receiving transmitted data. This included the construction of V-dipole receiving antennas and the development of ground-based software for mission operations.

The ground station development provided insight into the ground segment infrastructure that supports all space missions. Students gained experience with the complete communication chain, from satellite transmission through atmospheric propagation to ground reception and data processing.

Analysis and Validation

Thermal Environment Simulation

Using professional Radian software, students conducted comprehensive thermal analysis of their PocketQube designs. This critical phase involved modeling the space thermal environment, including solar heating, Earth albedo, and infrared radiation effects, then verifying that predicted component temperatures remained within operational limits.

The thermal analysis phase demonstrated the importance of understanding environmental conditions in space mission design. Students learned to identify thermal design challenges and implement solutions such as thermal coatings and component placement strategies to ensure mission success.

Structural Analysis and Launch Survivability

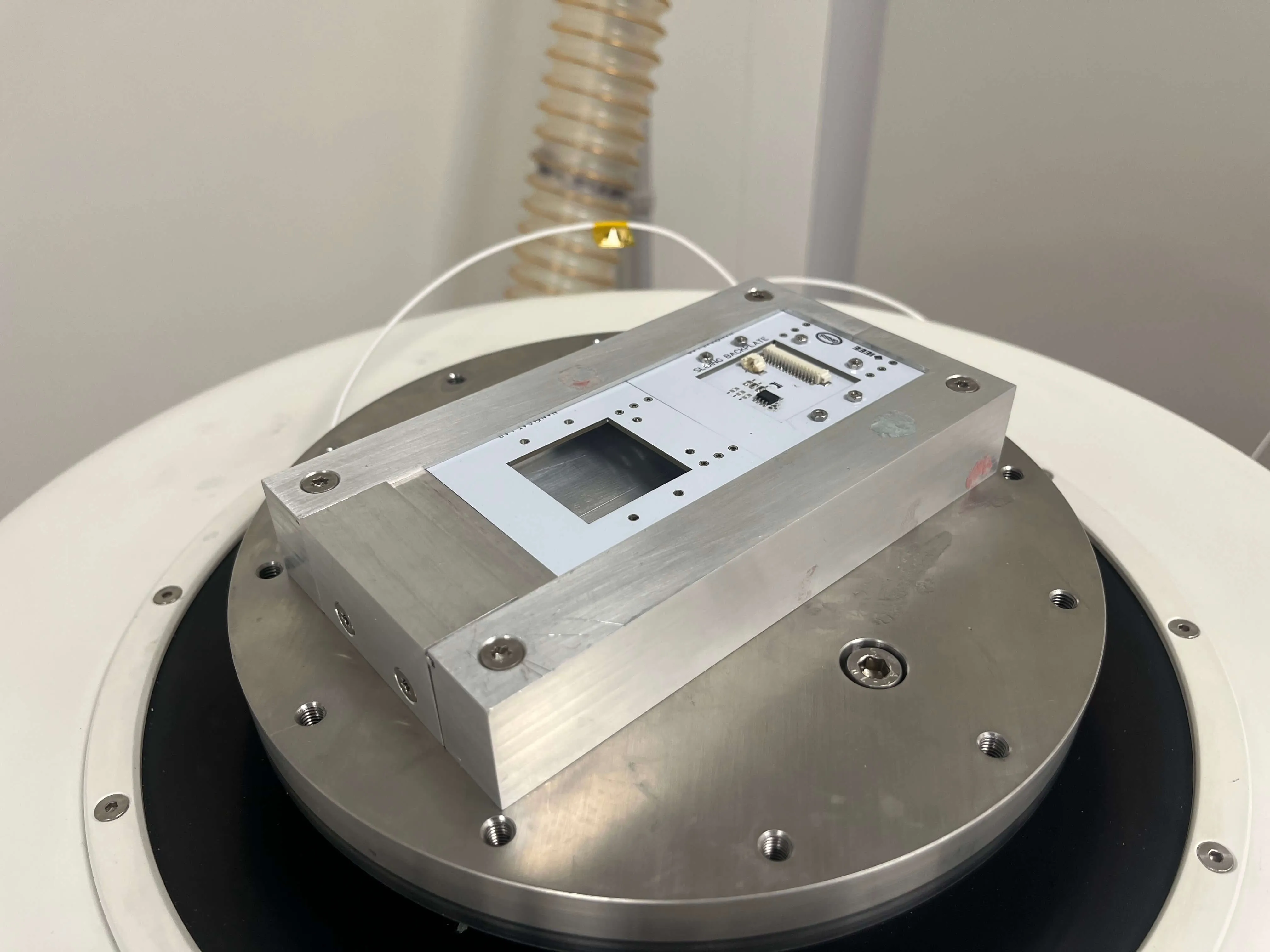

Working with ANSYS Mechanical simulation software, students performed structural analysis to verify their satellites could withstand the dynamic loads encountered during launch. This included modeling the effects of acoustic loading, vibration, and acceleration forces transmitted through the launch vehicle.

The structural analysis phase culminated in actual vibration testing using professional shake tables and accelerometer instrumentation. Students witnessed their designs subjected to realistic launch conditions, validating their analysis and gaining confidence in their engineering work.

Power Systems and Solar Integration

Students integrated solar power systems into their satellites, learning about photovoltaic cell characteristics and power management in the space environment. The power system development included both hardware assembly and software implementation for battery management and power distribution.

The solar panel integration phase involved practical testing with laboratory equipment including electroluminescence testing to verify solar cell integrity. Students gained understanding of how satellite orientation affects power generation and the critical relationship between power systems and mission operations.

Mission Operations and Testing

Full Functional Testing

Before mission simulation, each satellite underwent comprehensive Full Functional Testing (FFT) following space industry protocols. Students developed test procedures, executed systematic verification of all subsystems, and documented results using professional quality assurance methodologies.

The FFT phase demonstrated the critical importance of systematic testing in space missions. Students experienced the discipline required to verify that complex systems operate correctly under all anticipated conditions, learning that successful space missions depend as much on thorough testing as on innovative design.

Launch Simulation and Operations

The program culminated in a realistic mission simulation where students operated their satellites in an environment that closely mimicked actual space operations. Teams coordinated to acquire images using their custom payloads, transmit data through their communication systems, and receive information at their ground stations.

This operational phase required students to integrate all their technical work with operational procedures, demonstrating the human factors involved in space missions. Teams learned to coordinate complex activities under time pressure, experiencing the excitement and challenges of real satellite operations.

Educational Impact and Industry Relevance

The BIYSC 2025 program represents a significant advancement in space technology education, providing students with experience that bridges the gap between academic study and professional practice. Participants gained familiarity with the same tools, processes, and challenges encountered in commercial satellite development and space agency missions.

The comprehensive nature of the program ensured that students understood not only individual technical disciplines but also the systems integration challenges that define modern space missions. From requirements engineering through operations, participants experienced the multidisciplinary nature of space technology development.

Technical Achievements and Innovation

Each student team successfully completed a remarkable technical achievement: the design, manufacture, and operation of a functional satellite system. The PocketQubes developed during the program incorporated sophisticated technology including digital imaging systems, radio frequency communication, deployable structures, and autonomous software systems.

The program’s emphasis on manufacturing and hands-on implementation distinguished it from purely theoretical educational approaches. Students gained practical experience with the manufacturing constraints, quality control requirements, and integration challenges that influence real satellite development programs.

Looking Forward: Preparing Tomorrow’s Space Engineers

The success of BIYSC 2025 demonstrates the effectiveness of intensive, practical education in preparing students for careers in the rapidly expanding space industry. As commercial space activities continue to grow and new applications for satellite technology emerge, programs like BIYSC ensure that the next generation of engineers possesses both theoretical knowledge and practical experience.

The UPC-NanoSat Lab’s commitment to hands-on space technology education addresses a critical need in the space industry for engineers who understand not just individual technical disciplines but the complex interactions between subsystems that determine mission success. The comprehensive approach taken in BIYSC prepares students for the collaborative, multidisciplinary environment of modern space technology development.

The program’s integration of ethical considerations alongside technical training ensures that future space engineers understand their broader responsibilities as the space domain becomes increasingly important to global infrastructure and scientific advancement.

The Barcelona International Youth Science Challenge continues to set new standards in space technology education, combining rigorous technical training with hands-on experience using professional tools and methodologies. The UPC-NanoSat Lab’s innovative approach prepares students for leadership roles in the dynamic and growing space industry.